ÜCRETSİZ ALINTI

Product Description

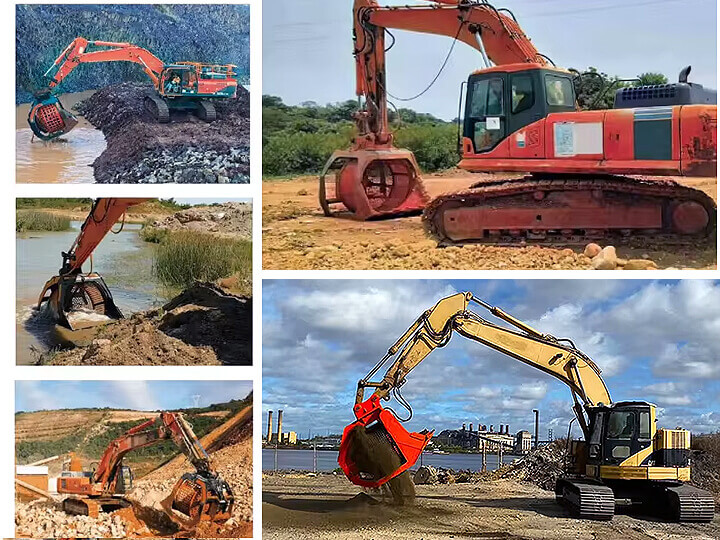

A rotary screening bucket, also known as a riddle bucket or shaker bucket, is a crucial attachment designed for excavators and loaders.

Functionality and Applications

- Function: Installed on excavators or loaders, the rotary screening bucket is used to sort natural materials both before and after crushing processes.

- Materials: Primarily used for screening sand, gravel, and soil materials (including dust). It is particularly effective for mountain and river sands, suitable for operations with high mud content.

- Applications: Commonly employed in washing operations, gravel screening, sand fields, mixing plant constructions, and various industrial sites.

Features and Design

- Screening Mechanism: Utilizes rolling screening technology that prevents screen holes from easily becoming blocked, ensuring consistent operation in diverse environments.

- Design: Features a split-screen design for easy maintenance and replacement, boasting a simple yet robust structure.

- Versatile Operation: The screening drum can rotate in both forward and reverse directions, enhancing overall screening efficiency.

- Screen Material: Constructed from imported wear-resistant materials, the screen holes are typically sized between 30-80mm for standard meshes. Custom screens tailored to specific working conditions can also be fabricated based on construction requirements.

Related Information

Excavator Screening Buckets:

The excavator screening bucket is a specialized attachment designed to enhance the versatility of excavators by transforming them into efficient screening tools. These attachments are meticulously engineered to sift through a wide range of materials directly on-site, minimizing the need for additional machinery and reducing operational costs. The screening bucket for excavator operates by utilizing a rotating drum or star screen mechanism, which effectively separates debris and unwanted materials from finer particles, such as soil, sand, and gravel. This process optimizes the workflow by allowing operators to screen and sort materials directly at the excavation site, thereby streamlining the entire construction or landscaping process. Screening buckets for excavators come in various sizes to accommodate different excavator models, ensuring compatibility and maximizing operational efficiency. Even mini excavators can benefit from a dedicated mini ekskavatör screening bucket, enabling them to perform screening tasks in tight spaces or confined environments where larger equipment may be impractical. Overall, these innovative attachments play a crucial role in modern construction and earthmoving projects, enhancing productivity and reducing the environmental footprint associated with material handling operations.

Loader Screening Buckets:

Our skid steer screening buckets are meticulously engineered to optimize efficiency and versatility in a variety of applications. Designed specifically for compatibility with skid steer loaders, these attachments offer unparalleled screening performance, making them ideal for construction, landscaping, and recycling operations. Available for both sale and rent, our skid steer screening bucket lineup ensures flexibility to meet diverse project needs without compromising on quality or durability. Similarly, our loader screening buckets deliver robust performance and are tailored to fit loaders seamlessly, enhancing productivity and reducing downtime. Whether you choose to purchase or rent, our loader screening buckets are equipped to handle demanding tasks with ease, ensuring optimal material sorting and processing efficiency. Trust in our commitment to delivering high-performance screening solutions that meet the rigorous demands of modern construction and industrial environments.

Rock Screening Buckets:

The Rock Screening Bucket is designed to sift out rocks, brush, and large debris efficiently, while preserving fill material integrity. By minimizing waste and enhancing machine productivity, it optimizes performance across diverse applications in construction, landscaping, and mining industries.